Turkey Prepares for a Major Earthquake by Redesigning Its Industrial Map

TurkeyEarthquakeErdogan_CM

TurkeyEarthquakeErdogan_CM

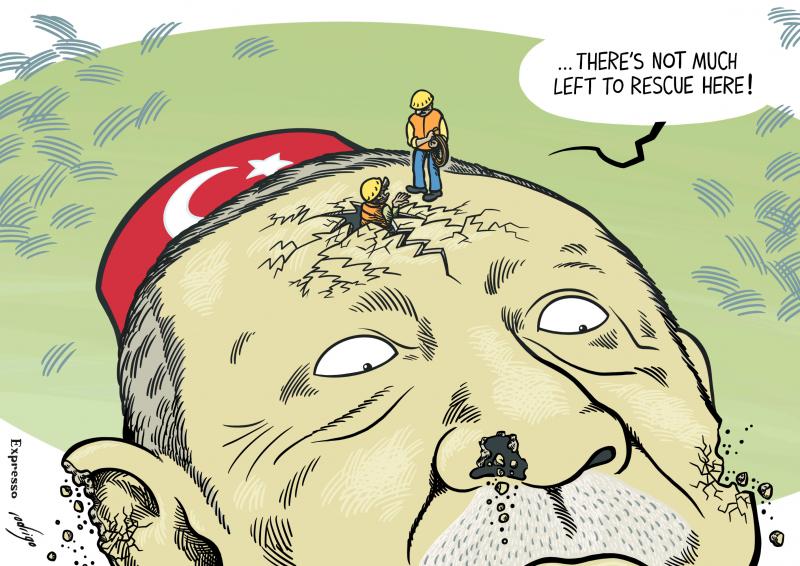

Turkey’s economic management is moving to proactively address one of the country’s most critical structural risks: the heavy concentration of industrial production around Istanbul and the wider Marmara Basin, an area highly exposed to major earthquakes. In response to the long-anticipated Istanbul earthquake, authorities are rolling out an ambitious framework, the National Industrial Zones Master Plan, aimed at transforming Turkey’s traditionally single-centered industrial structure into a more resilient, geographically balanced model.

At the heart of the initiative lies a simple but urgent reality. The Marmara Region functions as the backbone of Turkey’s manufacturing, logistics, and export ecosystem, yet it also sits directly on active fault lines. A major seismic event in this region would not only pose a humanitarian crisis but could also paralyze national production, disrupt global supply chains, and trigger long-lasting economic instability. The new master plan seeks to reduce this systemic vulnerability by decentralizing industrial capacity and spreading production across safer regions of Anatolia.

Marmara’s Industrial Power Meets Seismic Risk

Marmara is home to Turkey’s most advanced industrial clusters, dense logistics corridors, and a significant share of the country’s Organized Industrial Zones (OSBs). However, many of these facilities operate in first-degree earthquake zones, where even moderate seismic activity could cause severe damage. Provinces such as Istanbul, Kocaeli, Sakarya, Bursa, İzmir, and Tekirdağ stand out as both industrial powerhouses and high-seismic-risk areas.

Economic planners emphasize that resilience cannot rely solely on retrofitting factories or strengthening buildings. Structural resilience now requires redistributing production across the nation’s geography, ensuring that no single earthquake can disrupt the nation’s industrial heart.

Minister Kacır: “This Is Not Just Disaster Policy, It’s Development Policy”

According to the ministry, encouraging large manufacturers to relocate or expand into Anatolia will simultaneously reduce earthquake exposure, create local employment, and accelerate regional economic development. The approach reframes disaster preparedness as an opportunity to unlock underutilized labor markets and infrastructure nationwide.

Scientific Backbone: Kandilli Rasathanesi Steps In

To ensure the plan is grounded in science rather than assumption, the Ministry of Industry and Technology has partnered with Boğaziçi University’s Kandilli Observatory and Earthquake Research Institute. This collaboration represents one of the most comprehensive industrial risk assessments ever conducted in Turkey.

Within the scope of the study, 77 Organized Industrial Zones across eight provinces—including Istanbul, Kocaeli, Sakarya, and Bursa—are undergoing detailed seismic evaluation. The analysis extends beyond factory buildings to include energy transmission systems, transportation corridors, and critical logistics infrastructure. Findings from these studies will feed into a forthcoming “Industrial Site Selection Guide”, designed to help investors and manufacturers make data-driven decisions about safer locations.

Identifying Turkey’s New “Safe Harbor” Industrial Zones

The General Directorate of Mineral Research and Exploration (MTA) reports that 45 Turkish provinces lie on active fault lines, highlighting the limited number of truly low-risk regions. Based on seismic classifications, the government has prioritized fourth- and fifth-degree earthquake zones for future industrial development.

Among the leading destinations is the Central Anatolia Industrial Axis, encompassing Ankara, Eskişehir, Konya, Kayseri, Niğde, Aksaray, Nevşehir, Kırşehir, and Yozgat. These provinces combine relatively low seismic risk with improving transport connectivity, skilled labor pools, and available land for large-scale industrial development.

In parallel, strategic “gateway” provinces in the Black Sea and Mediterranean regions, such as Kastamonu, Samsun, Mersin, and Karaman, are being positioned as logistics and production hubs capable of supporting both domestic distribution and export routes.

A Risk Snapshot of Today’s Industrial Landscape

Current data reveals the urgency of the transformation. A substantial portion of Turkey’s top 500 industrial enterprises continues to operate within high-risk seismic zones. Bursa, despite hosting the highest number of OSBs in the country, is intersected by active faults. Kocaeli and İzmir, key centers for steel, petrochemicals, and heavy industry, face similar challenges.

This concentration creates what economists describe as a “single-shock vulnerability,” in which a single large earthquake could simultaneously halt production, damage infrastructure, and disrupt employment across multiple sectors.

Redefining Industrial Resilience for the Future

The National Industrial Zones Master Plan signals a paradigm shift in Turkey’s definition of economic security. Rather than reacting after a disaster strikes, the state is embedding earthquake risk management directly into industrial policy. If successfully implemented, the strategy could not only safeguard production but also reshape Turkey’s long-term growth model by making it more inclusive, regionally balanced, and resilient.

In an era where supply chain stability is as critical as cost efficiency, Turkey’s move to decentralize its industrial base may become a case study in how disaster preparedness and economic development can move forward together.